In the world of industrial infrastructure, cooling towers stand tall as towering sentinels of temperature regulation. These structures, often looming over industrial landscapes, play a crucial role in maintaining the thermal balance of various processes, from power generation to chemical manufacturing. Despite their imposing برج خنک کننده, cooling towers are often misunderstood or overlooked in discussions about industrial infrastructure. However, their significance cannot be overstated.

Understanding Cooling Towers:

At its core, a cooling tower is a specialized heat exchanger designed to remove heat from a process by transferring it to the atmosphere through evaporation. They are commonly associated with large-scale industrial facilities, particularly those involved in power generation, such as coal, natural gas, or nuclear power plants. However, they are also prevalent in other industries, including petrochemical, manufacturing, and HVAC (heating, ventilation, and air conditioning) systems.

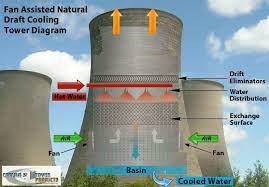

Cooling towers operate on the principle of evaporative cooling, leveraging the natural properties of water to dissipate heat. Warm water from industrial processes is pumped into the tower and distributed over a large surface area, typically through a system of nozzles or spray heads. As this water cascades downward, it is exposed to ambient air moving upward through the tower. Through evaporation, heat is transferred from the water to the air, lowering the water temperature.

Types of Cooling Towers:

Cooling towers come in various shapes, sizes, and configurations, each tailored to specific industrial requirements and environmental conditions. The two primary classifications of cooling towers are:

- Natural Draft Cooling Towers: These are characterized by their large hyperbolic or “chimney-like” structures. Natural draft towers rely on the buoyancy of heated air to create an upward airflow, drawing in cooler air from the base of the tower. This natural convection process eliminates the need for mechanical fans, making them energy-efficient but generally larger and more expensive to construct.

- Mechanical Draft Cooling Towers: In contrast, mechanical draft towers utilize fans or blowers to force air through the tower. They are further categorized as either induced draft or forced draft, depending on whether the fans are located at the top (induced draft) or bottom (forced draft) of the tower. Mechanical draft towers offer greater flexibility in design and can be more easily adapted to specific site conditions and cooling requirements.

Applications and Importance:

The significance of cooling towers in industrial processes cannot be overstated. They play a vital role in maintaining optimal operating temperatures for equipment and machinery, thereby ensuring efficiency, reliability, and safety. Some key applications include:

- Power Generation: Cooling towers are integral to thermal power plants, where they are used to cool the circulating water in steam condensers. By dissipating heat from the condenser, cooling towers enable the efficient operation of turbines and generators, maximizing electricity generation output.

- Chemical and Petrochemical Industries: In chemical manufacturing processes, cooling towers are utilized to control temperatures in reactors, distillation columns, and other equipment. They are also essential in petrochemical refineries for cooling various streams and condensing vapors.

- HVAC Systems: Cooling towers are commonly employed in large-scale air conditioning systems to cool water for building cooling. They provide an energy-efficient method for heat rejection, particularly in commercial and industrial buildings.

- Data Centers: As the demand for data processing and storage continues to rise, cooling towers are increasingly used in data centers to dissipate the substantial heat generated by servers and other IT equipment.

Environmental Considerations:

While cooling towers play a crucial role in industrial processes, they are not without environmental implications. One significant concern is the potential for water consumption and the discharge of warm water into natural water bodies, which can have adverse effects on aquatic ecosystems. Additionally, the formation of drift, which consists of small droplets of water entrained in the air exiting the tower, can lead to localized environmental and health issues.

To address these concerns, advancements in cooling tower technology have focused on improving water efficiency, reducing drift emissions, and implementing alternative cooling methods, such as dry or hybrid cooling systems. Additionally, regulations and standards governing the design, operation, and environmental impact of cooling towers continue to evolve, driving industry-wide efforts towards sustainability and environmental stewardship.

Conclusion:

Cooling towers are indispensable components of modern industrial infrastructure, playing a fundamental role in maintaining thermal balance and operational efficiency across a wide range of industries. While often overshadowed by other industrial equipment, these towering structures represent the intersection of engineering ingenuity, environmental responsibility, and industrial necessity. As industries continue to evolve, so too will the role and significance of cooling towers in shaping the landscape of global manufacturing